In the new era where technology and environmental protection intertwine, SmartCmeta is using innovation as its brush and graphene as its ink to write a new chapter in the field of new materials. As a subsidiary of MSTN Group, SmartCmeta has taken root in the Xiamen Torch Graphene New Materials Industrial Park since 2022. With its green, large-scale production line capable of producing hundreds of tons of graphene oxide annually, the company has become a pioneer in the industrial application of graphene.

Graphene oxide, as a significant derivative of graphene, is characterized by the introduction of abundant oxygen-containing functional groups onto the pristine graphene sheet structure. This not only preserves some intrinsic properties of graphene but also endows it with novel, easily processable chemical characteristics, serving as a "critical bridge" connecting cutting-edge laboratory research to large-scale applications.

Six Core Advantages of Our Graphene Oxide:

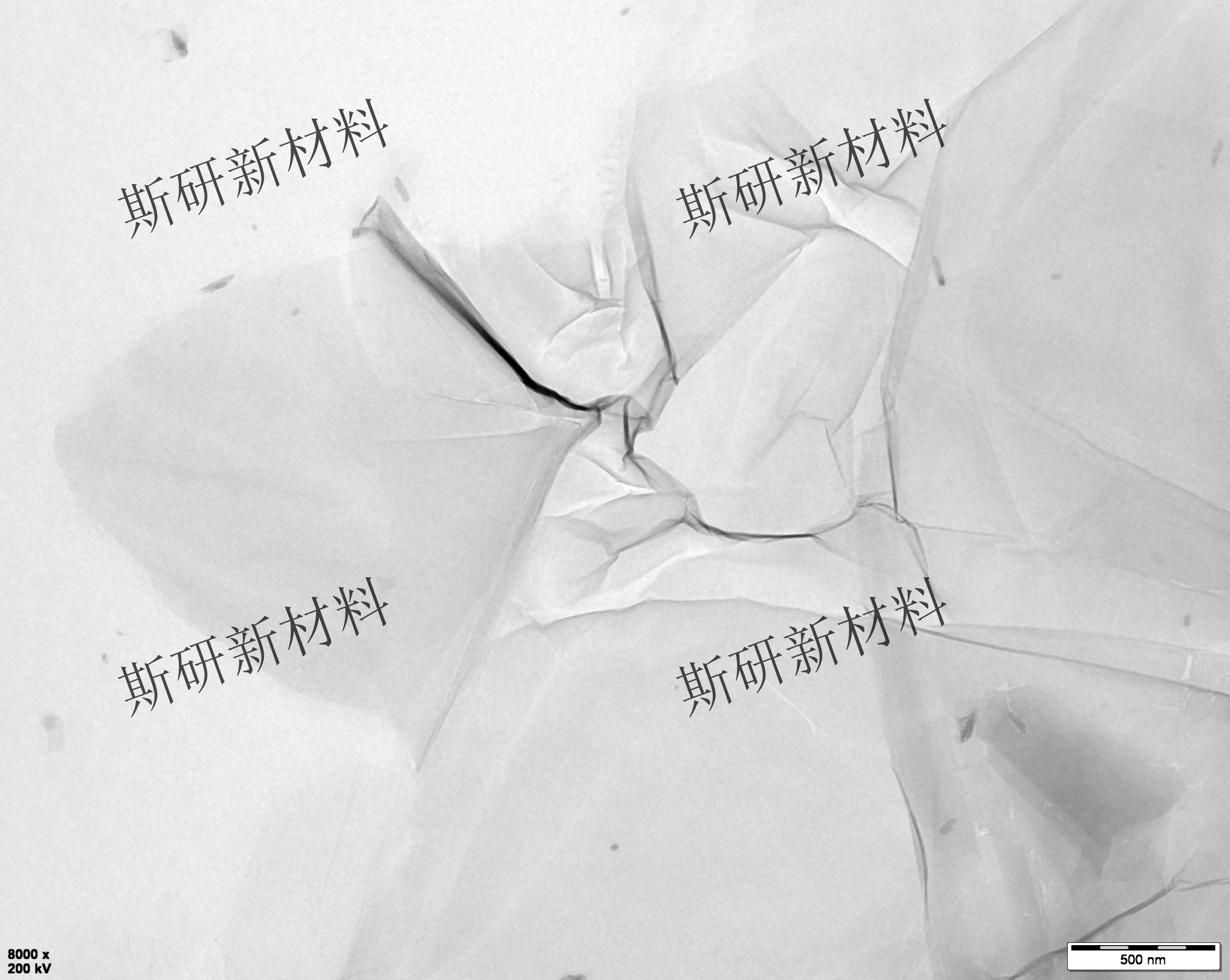

1. Atomic level thickness, abundant active sites

Graphene oxide has a two-dimensional planar structure with a single atomic layer or a few atomic layers, and this atomic level thickness brings about a huge specific surface area. If one gram of graphene oxide material is fully unfolded, its surface area exceeds that of a standard basketball court. This provides a large number of sites for catalytic reactions, loading of active substances, or efficient adsorption, which is the physical basis for improving the performance of various composite materials.

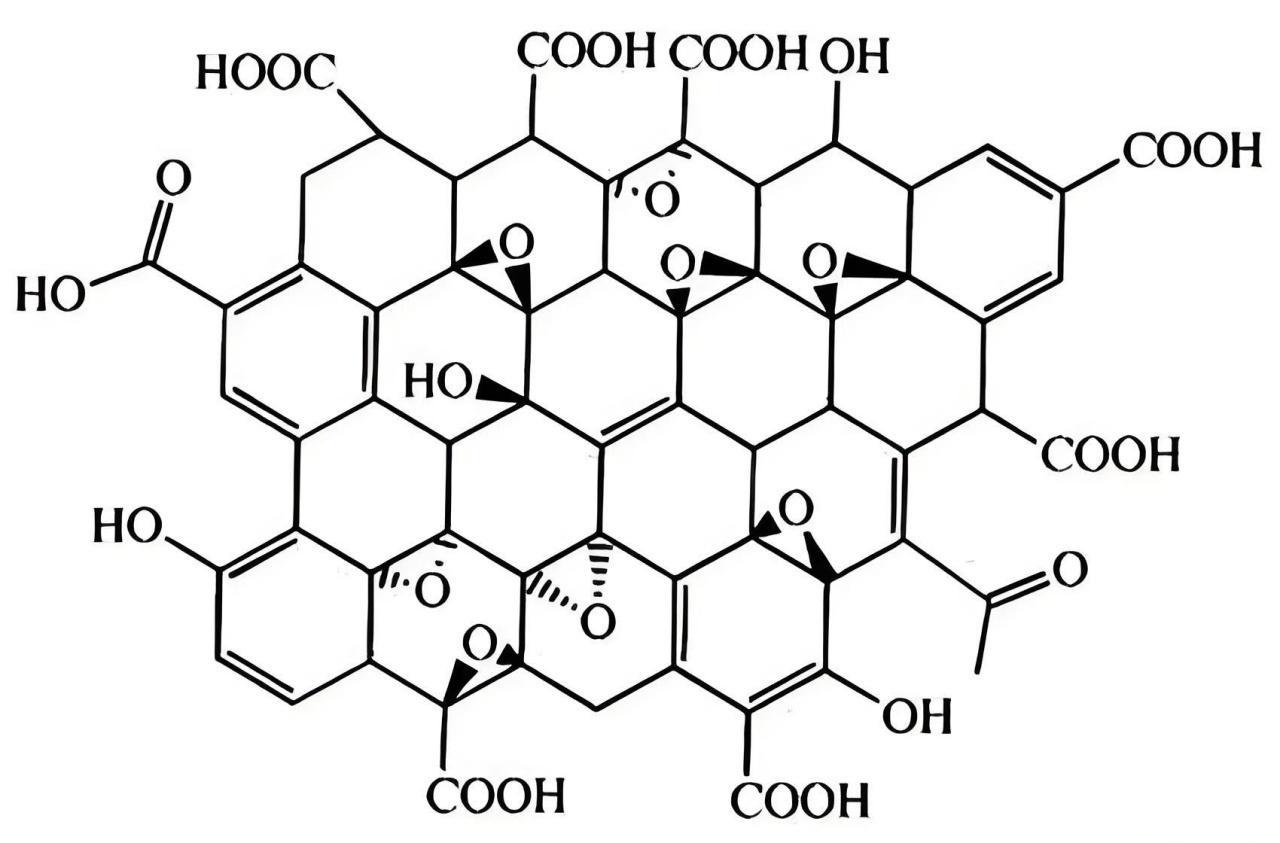

2. . Rich surface functional groups, enabling functional customization

The surface of graphene oxide contains abundant oxygen-containing functional groups such as hydroxyl, carboxyl, and epoxy groups. These functional groups are like "smart grippers" on the surface of materials, which can be combined with polymers, inorganic substances, or biomolecules through chemical grafting, cross-linking, modification, and other methods. This means that we can customize the functionality of graphene oxide according to the needs of end applications, endowing it with specific properties such as hydrophilicity, hydrophobicity, and antibacterial properties.

3. Excellent solution processability, easily integrated into existing processes

Graphene oxide can form stable dispersions in water or specific solvents. This characteristic enables it to be easily processed through mature industrial wet processes such as spraying, spin coating, scraping, filtration, spinning, etc., just like ordinary solutions. This significantly reduces the application threshold, allowing customers to easily make it into high-performance films, fibers, or uniformly composite it into various matrix materials.

4. Magical self-assembly properties, constructing three-dimensional macroscopic materials

Dispersed graphene oxide sheets can be spontaneously arranged and assembled in an orderly manner through hydrogen bonding, π - π stacking, and other forces. Using this characteristic, we can construct three-dimensional macroscopic materials such as graphene aerogel, hydrogel and high-strength self-supporting membrane. The leap from nanoscale two-dimensional materials to practical three-dimensional macroscopic structures has been achieved, opening up new application paths in lightweight, adsorption, energy storage and other fields.

5. Insulators and controllable reduction of performance to achieve intelligent performance control

The oxidation process destroys the original conjugated conductive network of graphene, making it an insulator. However, this has become a unique advantage: we can precisely control the degree of reduction through chemical, thermal, or photo reduction, thereby restoring its conductivity/thermal conductivity on demand and in a gradient manner. Thus, in a material system, intelligent design can be achieved from the insulation zone to the conductive zone, meeting complex requirements such as flexible electronics and intelligent coatings.

6. Adjustable layers and sizes to meet diverse application scenarios

Through precise production processes, SmartCmeta can provide graphene oxide products with different sheet sizes and specifications. Customers can choose the most suitable specifications based on their specific application requirements for material penetration threshold, transparency, and viscosity, achieving the optimal balance between performance and cost.

To help customers maximize the advantages of graphene oxide, SmartCmeta provides three forms of products: powder, filter cake, and dispersion. Whether customers are in the laboratory exploration stage or have already moved towards large-scale production, they can find the most convenient raw material solutions to accelerate the transformation from creativity to product.

Application field

With the above characteristics, high-quality graphene oxide is becoming a core material driving the upgrading of multiple strategic emerging industries:

Advanced environmental protection field: used to prepare oil-water separation materials with ultra-high oil absorption rate, filter cartridges with efficient adsorption of pollutants, and catalyst carriers for driving photocatalytic degradation of pollutants, contributing technological strength to green mountains and clear waters.

High performance composite materials: as nano additives, integrated into plastics, rubber, resins, coatings or cement materials, can significantly enhance the strength, toughness, thermal conductivity, electrical conductivity or barrier properties of the matrix material, creating the next generation of lightweight and high-strength materials.

Biomedical and Health: Utilizing the excellent biocompatibility and large specific surface area of graphene oxide, we aim to develop biosensors, drug targeted delivery systems, antibacterial dressings, or tissue engineering scaffolds, leading innovation in the field of big health.

Intelligent Electronics and Sensing: Used for preparing transparent conductive films, flexible strain sensors, temperature and humidity sensors, etc., it is an ideal material for future flexible electronics and IoT devices.

Start Your Partnership With MstnLand

Learn More